Shift Start-up Meeting and Primary Visual Display | Lean Daily Management System

By Sean Wright

Could routine communication around an information board with important facts keep everyone on track?

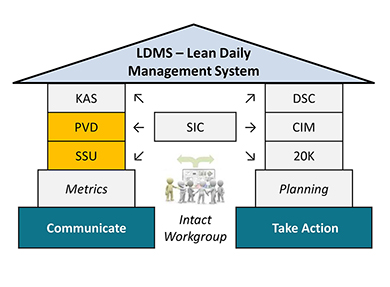

In the last post, I introduced the Lean Daily Management System and its seven vital components. As a rule, the first two of these put in place are the Shift Start-up Meeting daily huddles and the Primary Visual Display to post and share relevant performance data. These two LDMS building blocks are central to “intact workgroup” engagement for problem-solving informed by metrics that the workgroup itself can influence and control. Let’s take a closer look under the hood.

In the last post, I introduced the Lean Daily Management System and its seven vital components. As a rule, the first two of these put in place are the Shift Start-up Meeting daily huddles and the Primary Visual Display to post and share relevant performance data. These two LDMS building blocks are central to “intact workgroup” engagement for problem-solving informed by metrics that the workgroup itself can influence and control. Let’s take a closer look under the hood.

Shift Start-up (SSU) Meeting

The SSU communicates through a sequenced agenda tracking the layout of the workgroup’s PVD.

Description: Whether in the office or factory, the shift start-up meeting (sometimes referred to as a “huddle”) is a daily forum for communication, participation and team building. It provides a consistent approach for information sharing, delegating action and progress. It’s structured to drive workgroup awareness and involvement promoting small improvements every day. Key dimensions include:

- Five to 10 minute “stand-up” meeting

- Held in the work area at the PVD

- Led by rotating facilitators

- Headline type status review – last shift, this shift, next shift with facts, by the numbers

- Decisions and actions are documented with next steps captured on the PVD

- Any “Hot Buttons” opportunities are captured and assigned to team members to resolve

- In deference to focus and time available, take planning and other discussions offline

An associate leads the shift start-up meeting in front of the workgroup’s primary visual display

About SSU Workgroups: A SSU’s participants are its “intact workgroup”. While it may seem obvious what this term might mean, it’s foundational to LDMS so we’ll define it now… intact workgroups are:

- A group of hands-on workers who work near each other on similar processes or functions every day

- Responsible for their area, accept that ownership and are empowered to make decisions

- Customarily full-time with the team and able to meet daily

- Sized to foster effective communication with each group ideally being 7 +/- 2 people

As part of LDMS, leadership, management and supervision interacts with the workgroup in structured episodes to coach, teach and train the people in decision-making and problem-solving skills with the ultimate goal for intact workgroups to become “self-directed”.

We often get questions about intact workgroups who are physically collocated (often seems easier to roll out and implement) and those whose needs may require a virtual deployment (at first blush can appear more difficult to get useful results). Business today has broad geographic demands and sophisticated talent distribution, some of whom may have short-term contracting relationships to the enterprise.

We can’t do too much about time zone offsets for shared meeting starts. Someone may end up with a lousy time-of-day to participate in SSU meeting. Still, contemporary collaboration technologies such as Microsoft Teams can be extraordinarily useful here. For many years such platforms have enabled a “place” to meet with purpose, context and file support for a production session. Such a robust tech ecosphere helps assure that geographically and temporarily displaced ‘intact workgroups’ are engaged. At Kaufman Global, whether on office or factory improvement projects, our own project workgroups depend on these same virtual protocols to assure value-added collaboration and ongoing improvement occurs.

Primary Visual Display (PVD)

A PVD is the workgroup’s visual info hub; its core metrics reveal what’s important and how we’re doing.

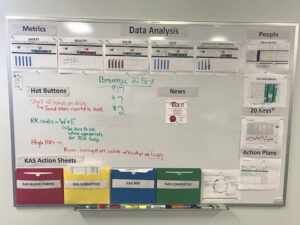

PVD displays workgroup metrics and is updated by the team at every shift.

Description: The Primary Visual Display (example, inset left) is the main information hub located within each work area. (There are surely supplemental visuals for other purposes, hence why this specific board is referred to as the “primary” display.) The PVD is the focal point for a workgroup’s shift start-up meeting and is where performance is posted and tracked. PVD metrics — typically displayed as hand marked-up graphs, tables and charts — are those that the workgroup itself can influence and control. For convenience and consistency, the SSU meeting agenda tracks the PVD’s layout. The PVD is maintained by the workgroup and reflects practical performance topics such as those concerning:

|

|

About Workgroup PVD Metrics: Quite simply, workgroup metrics are numbers about the work that are important to the workgroup with respect to creating and sustaining customer value. Metrics are measurements over time that communicate vital status and trends about the work in aspects such as: safety, quality, throughput, inventory, costs and results. Metrics serve to spotlight customer-facing needs, align with organizational performance objectives and cultivate process awareness. They’re pivotal in advancing continual improvement.

When they include a baseline (how we’re doing today) and a goal (where we want to be), metrics are the measurements that tell us how our process is performing against our goal. A missed goal informs when and what problem-solving tool or other countermeasure to apply and likely informs follow-on improvement activities or Kaizen events.

Many workgroups initially have challenges with identifying good metrics for their work processes and deliverables. Experienced coaching by local leadership when launching the SSU and PVD, and facilitation by third party resources can help bring clarity to these challenges.

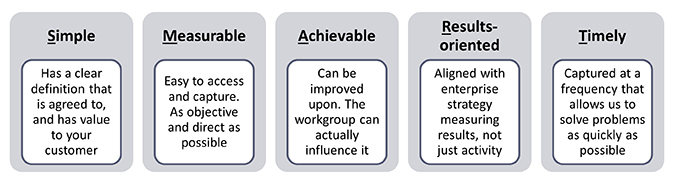

For example, good metrics have long been described as being “SMART” — that is: Simple, Measurable, Achievable, Results-oriented and Timely (example, inset above).

With that expectation as our North Star, we relay a brief awareness overview for workgroups focusing on what good metrics look like. Then, we work directly with each unit to inculcate applicable measures that reflect what the enterprise seeks to know about performance (ex.: attendance and downtime), as well as specific measures that inform the local work product (throughput, percent reporting errors, etc.) Whether in offices or factories, the metrics selected are as varied as the type of work. Still, all enterprises worldwide (regardless of factory or administrative focus) favors some constants by observing measures that reflect safety, quality, delivery, inventory and productivity. Whatever metrics are selected, they’re subsequently refined over time as data is taken and learning occurs to compel their change.

Next Time

In Part 3, we’ll cover the Kaizen Action Sheet system. Meantime, if you’d like to launch your LDMS workgroups off right – or, if you’ve already begun and you aren’t achieving the expected results, we can help. Kaufman Global offers: deep, real-world experience, world-class coaching and training at all levels, a rich array of intellectual property, learning materials, and Train-the-Trainer Certification programs all focused on solving real performance problems so you get a business boost while building capability.