Takt Time

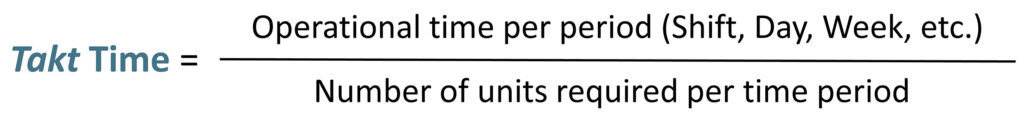

Takt Time in the context of Lean is the cadence that product must move through the production system. The term is German in origin and it means cadence, rhythm or tempo. The formula for is: Operational Time Period / Units Required per Time Period.

For example, if customers demand 240 widgets and the factory operates 480 minutes per day, takt time is two minutes. If customers want two new products designed per month, takt time is two weeks. This sets the pace of production to match the rate of customer demand and is at the basis of all subsequent production design calculations becoming the heartbeat of any Lean system. Think of this as the metronome that beats out a cadence that determines the synchrony production or output.

Takt time

- Determines the speed of the line or production system

- The time available to produce a component, single unit or even an entire finished product

- Is determined by the number of units required by the end of each day to meet the production target