Six Sigma

Six Sigma is a structured problem-solving, process improvement and quality management methodology composed of scores of integrated tools and techniques.

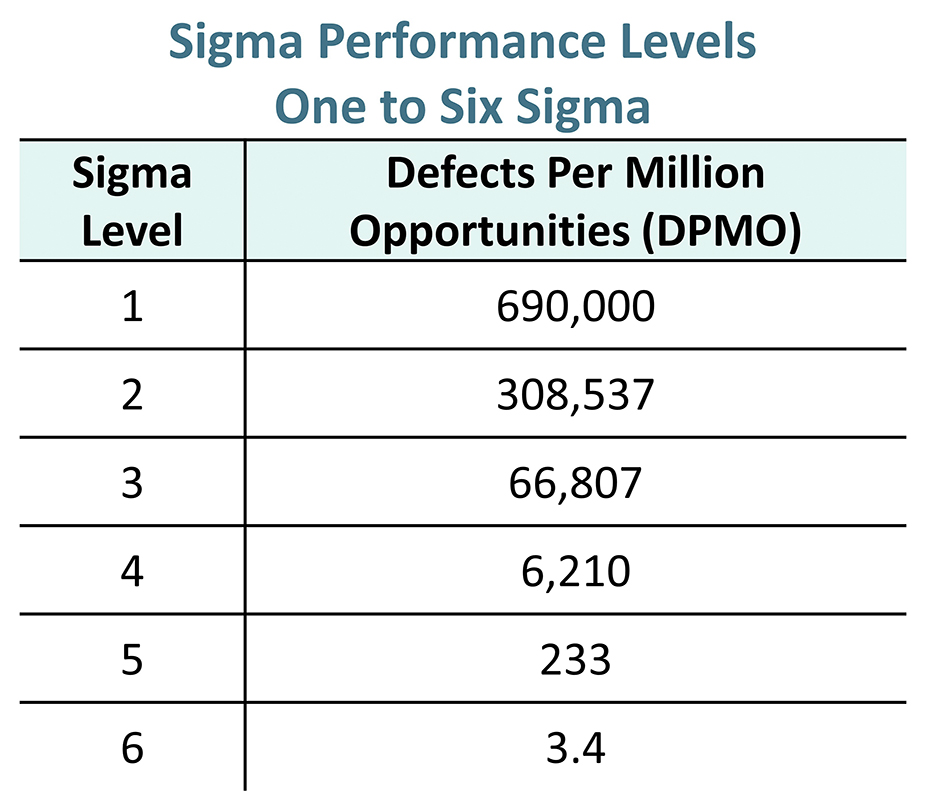

Trained and validated practitioners use focused projects and statistics to identify and isolate process variation in order to determine and implement appropriate countermeasures and promote stable processes. The overall intent is to reduce variability, errors and defects and achieve a six-sigma levels of performance — that is fewer than 3.4 defects per million — thereby lifting and sustaining product and service performance.

Six Sigma seeks to reduce variation to achieve process and quality excellence. Variation is a shift or change in in the attributes of a product or services, away from the prescribed “ideal”. It uses statistical methods to identify variation and target solutions. Some of the core analytical methods include:

- Cause & Effects (C&E), Ishakawa diagram

- Value flow analysis

- Histograms, run charts, pareto charts, box plots, scatter diagrams

- Hypothesis testing (means, variances, contingency table, normality testing

- Correlation and simple linear regression

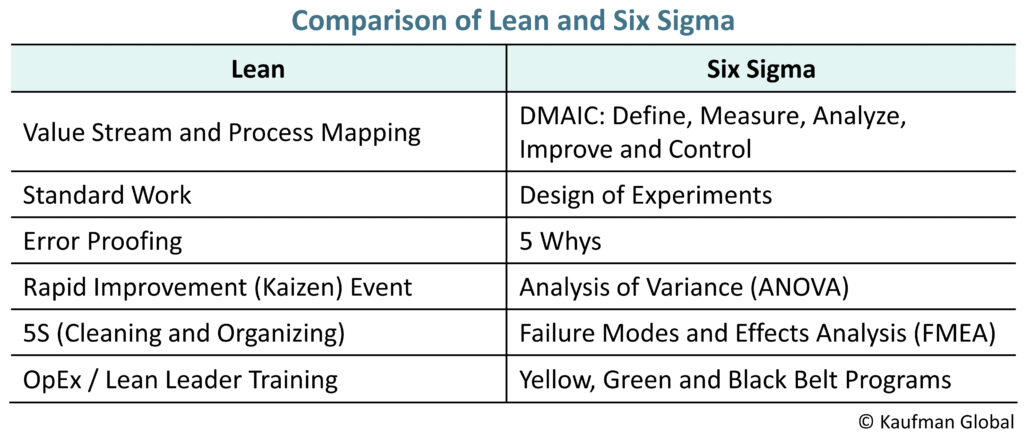

Six Sigma uses the DMAIC project management methodology: Define, Measure, Analyze, Improve, Control. The chart below shows a comparison between Lean and Six Sigma methods and approaches. Lean and Six Sigma along with change management approaches are the major elements in the Operational Excellence universe.