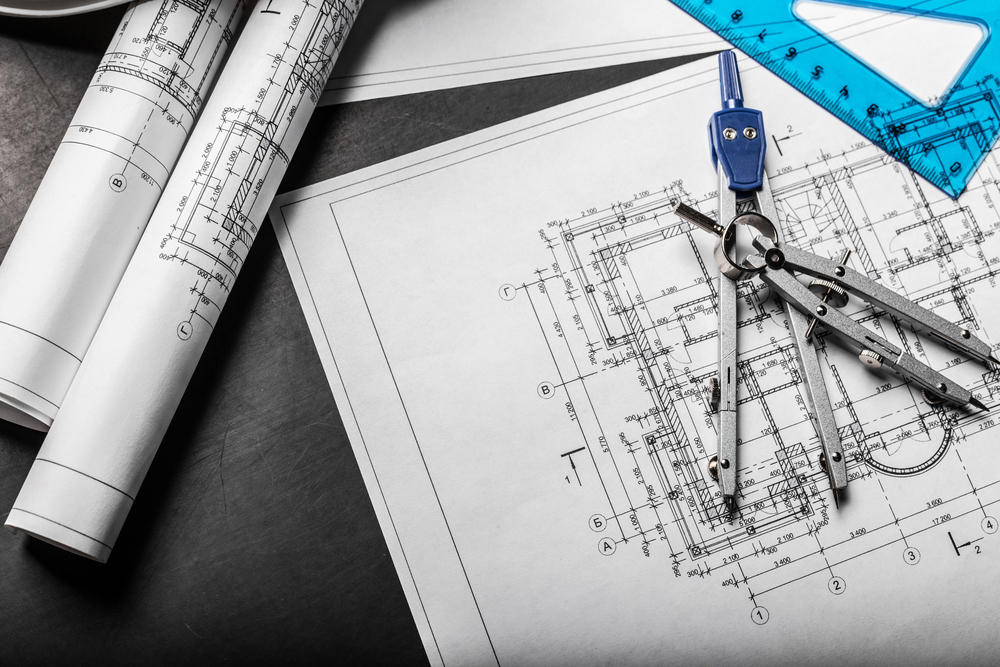

Project Highlights

Optimize facility layout, people, asset and work flows

Lean design process focuses on: distance, space, time

Considers: current vs. future capacity and HSE

Recommended changes ensure fit-for-purpose design

Footprint utilization

More avail workspace

Staff engaged in design

Less forklift movements

Less waiting for equip

Optimize facility footprint for capacity and functionality.

With a new oilfield services maintenance facility under construction, this client wished to engage Kaufman Global to review the functionality of the proposed workspace and assess footprint flexibility for future growth. Critical to this process is the ability to manage competing priorities and facilitate teams through a data-driven review of their value streams, capacity demands / future requirements and HSE considerations.

Work processes and capacity requirements were reviewed with the teams with a focus on material and people flows. These were superimposed on the available footprint to identify bottlenecks and building restrictions. Area designs were rationalized and combined into a complete picture and a facility-wide workshop was held to validate the design and gain consensus on the layout. The final result included 8 construction and 27 process recommendations agreed upon to enhance the functionality and footprint utilization of the workshop and yard.

“Given a complex problem, you have an enviable ability to find a simple solution. Your insistence on professional quality at each stage produced a much better result than we had originally thought possible. We appreciate your outstanding work in getting this new facility started right and we will certainly send any future projects requiring such expertise to your company.”

Get Results

Like These.

Real organization change requires fast action, fast impact and enduring confidence in their results. Put Kaufman Global to work for you.