Lean Daily Management System

The Lean Daily Management System (LDMS): Using Structure to Engage Employees and Optimize Value

In the late 1990s, when Kaufman Global developed the Lean Daily Management System® (LDMS®), we recognized that “Lean” as a method for improving business was often viewed as a set of tools aimed at machines and inventory. On the surface, and in the simplest of explanations, it was considered to be a group of useful techniques that could be “directed and applied”. I think this was more of a Western interpretation that still reverberates today. In this, the practitioners of the day put less emphasis on the human element and treated engagement as a collateral benefit of Lean, rather than the primary contributor to Lean results. Much of the information available focused on technical aspects such as pull systems, inventory leveling and quick change-over with a bias for discrete manufacturing versus continuous flow, business process or service industries.

Consider these highlights from the 1990s Lean landscape:

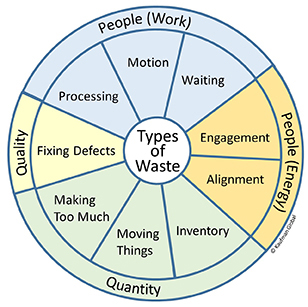

Taiichi Ohno’s original waste wheel updated with People Energy wastes: Engagement and Alignment

- Taiichi Ohno’s seven wastes had not yet been updated to include People Energy Wastes of Alignment and Engagement. This has since been added to present day waste wheel diagrams (right), but it is an addition that Ohno probably would agree with today. He keenly understood the value of engagement and human intellect when he said in his book Workplace Management (Ohno, 1988), “Only the gemba can do cost reduction.”

- The Machine that Changed the World (Womack, Jones, & Roos, 1990). For a decade this book was the primary source of Lean inspiration as manufacturers attempted to emulate Toyota. It is still a compelling description of the benefits of Lean vs. more traditional forms of production. The book describes worker engagement as an important element of the Toyota Production System but it does not peg it as the foundation. Lower inventories and improved product flow are viewed as the causes of higher productivity and better quality when they are actually the effects of a more engaged workforce.

- Learning to See (Rother & Shook, 1998). All about Value Stream Mapping, it is still the preferred source for this technique for understanding waste and value. It is most effective in manufacturing environments where inventory can be converted to time.

Power to the People

Our fundamental belief then and now is that Lean is a people system, not a technical one. Think of Lean tools like Quick Changeover, Error Proofing, Pull Systems, or Kaizen Events as waste elimination shovels. They work great, but they are useless without some keen insight about where to dig. This was the missing link we sought to address as we first described LDMS. It gives natural work teams the ability to make decisions about where to dig based on their understanding of their issues and performance. Combine this insight with the authorization for them to actually take control and utilize some structured problem solving techniques, and you have a self-regulating improvement engine.

The Lean Daily Management System Methodology

It’s about workgroup engagement:

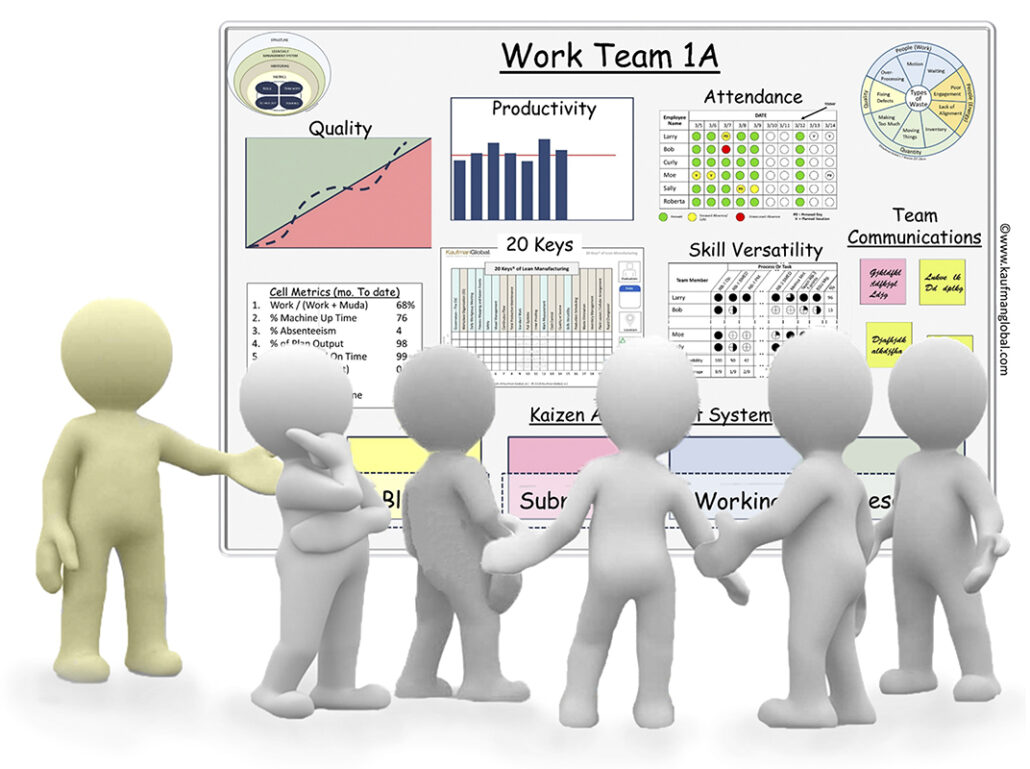

The Lean Daily Management System – Shift Start-Up meeting at a Primary Visual Display board.

The Lean Daily Management System is done by intact workgroups with common tasks and deliverables. They perform the standard procedures that help teams continuously improve their day-to-day work (Kaizen). Vital components of the Lean Daily Management System:

- A daily shift start-up meeting (SSU) (no more than 10 minutes) at the

- Primary Visual Display (PVD) board

- Kaizen Action Sheet (KAS) improvement system

- The 20-Keys® for assessment, planning and action

- Daily short interval coaching (SIC) by supervisors

The Lean Daily Management System is the primary means of engaging the broader organization. It is the manifestation of work group participation and this engagement is the fastest route to the overall objective of Lean which is to maximize customer value by minimizing waste. Or said another way: Deliver at each step what you need, when you need it, at ever-increasing levels of quality and customer satisfaction. While this cannot be achieved via top-down control, leadership does have an important part to play. “Doing” LDMS must be supported, expected, encouraged and required from above, otherwise it won’t happen consistently enough, broadly enough or often enough to become the way the organization does business.

LDMS Behaviors and Actions are Specific and Observable

The constructs of LDMS are specific. They describe activities and behaviors that are observable. This gives leadership a natural and specific way to interact with and support the teams. For example, one could ask: “Do you have good teamwork? Are you communicating? Do you measure your work and performance?” In an LDMS environment, all of these things are observable and the teams are able to speak directly to how they do it. That empowerment drives accountability and process ownership downward, where it belongs.

The constructs of LDMS are specific. They describe activities and behaviors that are observable. This gives leadership a natural and specific way to interact with and support the teams. For example, one could ask: “Do you have good teamwork? Are you communicating? Do you measure your work and performance?” In an LDMS environment, all of these things are observable and the teams are able to speak directly to how they do it. That empowerment drives accountability and process ownership downward, where it belongs.

The Lean Daily Management System gives organizations outside the realm of manufacturing something to grasp. When you think of Lean as waste elimination and LDMS as the standard work of an engaged organization, it opens a world of possibilities that go beyond the shop floor. In our experience, LDMS works everywhere. Contents are adjusted – metrics for example will be different in functional and administrative environments than in manufacturing. But when people actively participate in improving the work that they control, they always find ways to innovate and adjust appropriately.

Where is it working? Here are a few examples:

- Industry: Goodrich, AGCO, Becton Dickinson, Johnson and Johnson, Genentech, Haldex, IR, Goodyear, Owens Corning, Nabors

- Healthcare: Sutter Healthcare Systems, Oregon State Hospital, Mississippi State Hospital, Lincoln Healthcare Network

- Government: State of Oregon, State of Indiana, State of Delaware, UK Highways Agency

Why The Lean Daily Management System Works

Should you do it?.. Of course! LDMS makes Lean sticky.

- People have more personal control and ownership of the work that they do. Individual and team accomplishments become visible.

- Performance issues and opportunities are more transparent.

- Process changes and improvement efforts are better connected to day-to-day activities and standard work is easier to achieve.

- LDMS engages minds and hearts and provides a vessel for employees to contribute in ways that are meaningful and rewarding to them.

Even with all these positives, be prepared for some resistance. It’s something new and people will have lots of questions as the system is coached into the organization. Leaders needs to be encouraged to stay the course until the culture starts to recognize that a broad and proactive approach to performance improvement is the best way to eliminate waste and improve customer value.

********************

Kaufman Global began teaching and implementing the Lean Daily Management System in 1999. It was first described and published in our groundbreaking White Paper: WIn-Lean® Manufacturing in 2000.

In 2017 we updated our content to include even greater emphasis on the fact that the waste of People Energy (Engagement and Alignment) is still the greatest opportunity for any organization seeking to improve performance. For a full description of how and why LDMS fits into any Lean system, download a copy of our White Paper: Implementing Lean Manufacturing: A Holistic Approach.

Results from Kaufman Global clients who have implemented and are using the LDMS:

Oregon State Hospital uses the Lean Daily Management System and here: Oregon State Hospital Presentation

BD uses LDMS everywhere: BDs Corporate Citizenship Report – see page 36

Tier 1 automotive company that deployed the Lean Daily Management System globally

Pharmaceutical company uses LDMS as a cornerstone of enterprise Lean implementation

********************

References

Ohno, T. (1988). Workplace Management. Cambridge, MA: Productivity Press.

Womack, J., Jones, D., Roos, D. (1990). The Machine That Changed The World. Based on the Massachusetts Institute of Technology 5-million dollar 5-year study on the future of the automobile. New York, NY: Rawson Associates.

Rother, M., Shook, J. (1998). Learning To See: Value Stream Mapping to Create Value and Eliminate Muda.

Lareau, E. W. (2000) White Paper:WIn-Lean® Manufacturing.

Clients never say: “We want to transform and do better, but we don’t care if we sustain the improvements.” Clients always profess a sincere desire to sustain results. This intent is so pervasive that during the past 20 years we’ve seen the rise of Operational Excellence as a legitimate function across wide swaths of business and industry. Yet most organizations fail to realize this apparently lofty goal. Low levels of lasting success are usually explained at a tactical level, but the reasons that leaders and their organizations get it wrong goes much deeper.

Clients never say: “We want to transform and do better, but we don’t care if we sustain the improvements.” Clients always profess a sincere desire to sustain results. This intent is so pervasive that during the past 20 years we’ve seen the rise of Operational Excellence as a legitimate function across wide swaths of business and industry. Yet most organizations fail to realize this apparently lofty goal. Low levels of lasting success are usually explained at a tactical level, but the reasons that leaders and their organizations get it wrong goes much deeper. resulting in reduced effort and commitment just when their dedication is needed the most. How do you stop or prevent this from happening?

resulting in reduced effort and commitment just when their dedication is needed the most. How do you stop or prevent this from happening?

valuable information (i.e., “sticky data”). Commonly recognized as methods for gathering sticky data, the above technologies, when supported by a workforce, can transform real-time data into business intelligence generators that drive more accurate insights into key areas of the business. The simple truth is that without a structured program in place to target, collect, distribute, and analyze the most relevant data in real-time, organizations can be data rich but information poor.

valuable information (i.e., “sticky data”). Commonly recognized as methods for gathering sticky data, the above technologies, when supported by a workforce, can transform real-time data into business intelligence generators that drive more accurate insights into key areas of the business. The simple truth is that without a structured program in place to target, collect, distribute, and analyze the most relevant data in real-time, organizations can be data rich but information poor.