Teamwork is Essential for Lean Success

The likelihood of sustainable change is directly related to the degree to which that change is valued and supported by leadership, practiced by the organization, and consistently reviewed for improvement potential. Yet, how do you reach that level of cohesiveness — where everyone is fully engaged to eliminate waste, improve quality and drive innovation? Teamwork is the key. The simple truth is that implementing Lean is more than the adoption of a set of tools. Rather, success lies in developing new skills, new habits and, ultimately, a new culture. It’s a transition from a “traditional,” siloed work environment to one of high-performance teams where everyone participates.

How Lean Evolves

Opinions on how operations could and should be managed to maximize effectiveness have evolved. For millennia, family was the primary work unit. The family farm was a work and social system based on intimacy and trust. Personal  ownership, commitment and the resulting quality of the work were all high. However, efficiency suffered because tasks were not, in general, methodically optimized.

ownership, commitment and the resulting quality of the work were all high. However, efficiency suffered because tasks were not, in general, methodically optimized.

During the industrial age, assembly lines and mass production came into existence. Simplification narrowed the scope of individual work. Teamwork was discouraged and perceived by managers as insubordinate behavior. Regardless, production increased (i.e., more cars were manufactured at a lower price) which says a lot about the efficacy of mass production. On the assembly line, economic efficiency improved but social and psychological elements were sacrificed. The assembly line defied the common human behaviors of recognizing, discussing and resolving problems.

Today, Lean has become recognized as the most successful framework for operational excellence. When implemented to its full extent, a Lean organization has a clear focus on the flow of work that is being managed by highly knowledgeable teams empowered to make decisions. Not simply a work system, Lean is a management system and social system because it achieves both high levels of engagement and economic efficiency — key goals for every organization.

Teamwork Requires Leadership and Coaching

Engaging people in meaningful collaboration doesn’t happen on its own. While some level of cooperation to problem-solve is an innate human trait, so too is following orders and minimizing disruption. Unless given overt license to do so, people typically won’t form teams to solve day-to-day problems. Most of today’s traditionally run organizations still suffer from the assembly line mentality mentioned above. Simply introducing Lean tools or establishing a quality control group to address performance problems is a Band-Aid® solution. You may see a short term gain, but without a long-term strategy for continuing to improve and measure progress by the team that owns the process, backsliding is almost inevitable.

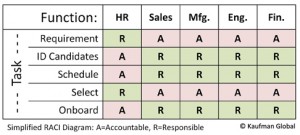

Effectively implementing Lean and sustaining results requires solid teamwork, led with discipline and reinforced with positive feedback. A basketball team doesn’t develop superior performance by practicing only when it’s in the mood. It will not improve by hitting the court in a random or disconnected manner. Furthermore, performance lags without a clear sense of roles and responsibilities and a game plan for each position on the team. Similarly, in order to develop the skills and habits of a Lean organization, there must be a clear plan and disciplined effort that supports, encourages and mandates teamwork.

The Lean Daily Management System ®(LDMS ®) is a proven method for actively connecting leadership and their teams to the work they do every day. Tying together practices like leader standard work, daily accountability, and visual controls, it provides a disciplined, structured and ongoing process for checking and adjusting the improvement cycle. LDMS focuses small, intact workgroups on continuously improving their day-to-day work processes. It cultivates new habits by establishing a foundation for leadership to engage employees and manage improvements.

Is your organization awash with “tools” but lacking a structure for them to be consistently and collaboratively applied? If so, I offer leadership simple advice. Engage the people who know the work best – at all levels and across all functions, arm them with methods they can apply and institute measures that are meaningful to them, then watch your teams really take flight.

Upon doing some research, there were no ground-breaking “bacon discoveries” to be found. However, I did learn about some healthier ways to prepare and eat it. Reading the countless available articles, I had a sudden epiphany. It hit me that the meticulous handling of bacon provides a valuable lesson. There’s a right and wrong way to do things, and, in many cases, the right way is neither the easier nor the faster path (but it’s still “the

Upon doing some research, there were no ground-breaking “bacon discoveries” to be found. However, I did learn about some healthier ways to prepare and eat it. Reading the countless available articles, I had a sudden epiphany. It hit me that the meticulous handling of bacon provides a valuable lesson. There’s a right and wrong way to do things, and, in many cases, the right way is neither the easier nor the faster path (but it’s still “the

That may mean completing a detailed process map, a

That may mean completing a detailed process map, a