Batch Production

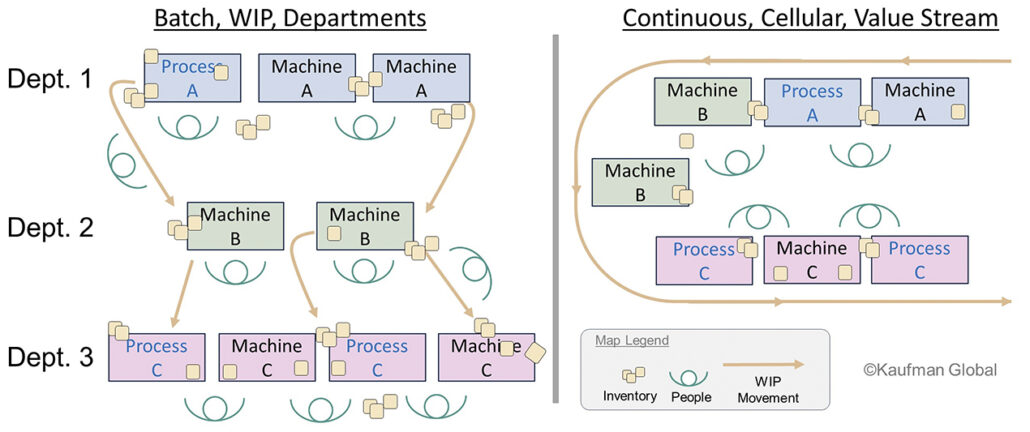

Batch production, or as its often referred to as batch-and-queue, is the practice of processing multiple units – also known as lots or batches – at the same time through a production process.

Contrasting with Single Piece Flow, batch dimensions are typically determined by production capacity, opportunity to fill idle time, and / or perceived convenience of minimizing set-ups and changeovers.

By its nature, batching can cache defects and / or delay their detection throughout one or more production stages. Such flaws can result in large quantities of scrapped work-in-process or finished goods — surely a waste. As well, many classic lean simulations demonstrate time and again that batch-and-queue vs. single piece flow involves more labor with longer lead time to deliver its first good part later.

Batch production can work for select situations. For example, it’s often used in the food preparation sector. Batching can relay higher efficiencies than Job Order based production systems. As well, it may alleviate changeover frequency in heavy industries that face severe downtime hardship when performing equipment or tooling reconfigurations. Similarly, the choice to batch may be an issue of how best to deploy a shortage of highly skilled tradespeople to multiple sequential production tasks.

Yet, for many settings, batch production doesn’t tend to best optimize inventory, storage space, efficient resource deployment, nor the means of production.

A transition from legacy batch production operations to something else could take some time. First, a thoughtful analysis is needed to justify any particular production configuration rather than leaping to batch, job or single piece flows. But more than that, it’s a matter of changing the hearts and minds of managers and workers who are often tightly invested in batch system know-how and simply don’t consider effective alternatives.

« Back to Glossary Index