A3 Process

The A3 process is problem solving, project management and communication template for operational improvement. Its strength is a standard approach to documentation and communication. The template is contained on a single sheet of A3 sized paper: (11x17in) or (29.7 x 42cm).

The template and process is based on the idea that it is easier to manage and communicate improvement projects by confining the space allowed for the document itself. When done well, the final document is simple, clear and focused. Because of this, it is easier to build consensus about the path forward.

A3’s were originally used at Toyota to develop the scientific thinking skills of employees under the guidance of a coach. The format helps teach and reinforce the importance of:

- Clear objectives

- Experiments to solve problems

- Facts and data for better solutions

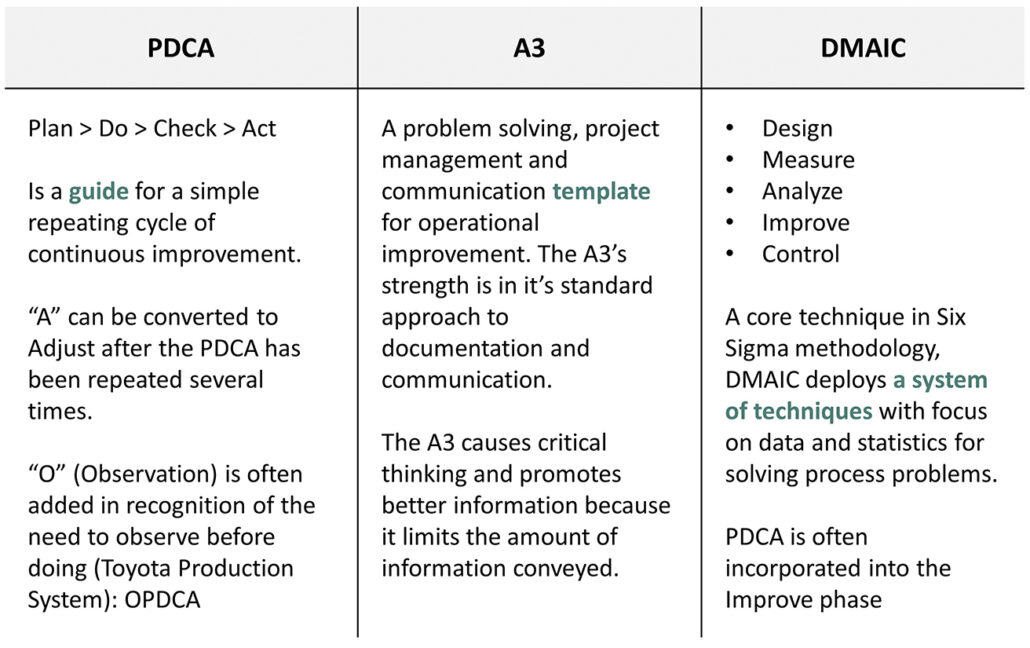

The A3 process is based on the principles of Edward Deming’s PDCA (Plan-Do-Check-Act). DMAIC (Design, Measure, Analyze, Improve and Control) is a system of techniques that is at the heart of six-sigma. All three of these problem solving techniques are closely related. The table below gives a comparison of the three methods.

Comparison of PDCA, A3 and DMAIC Improvement Methods

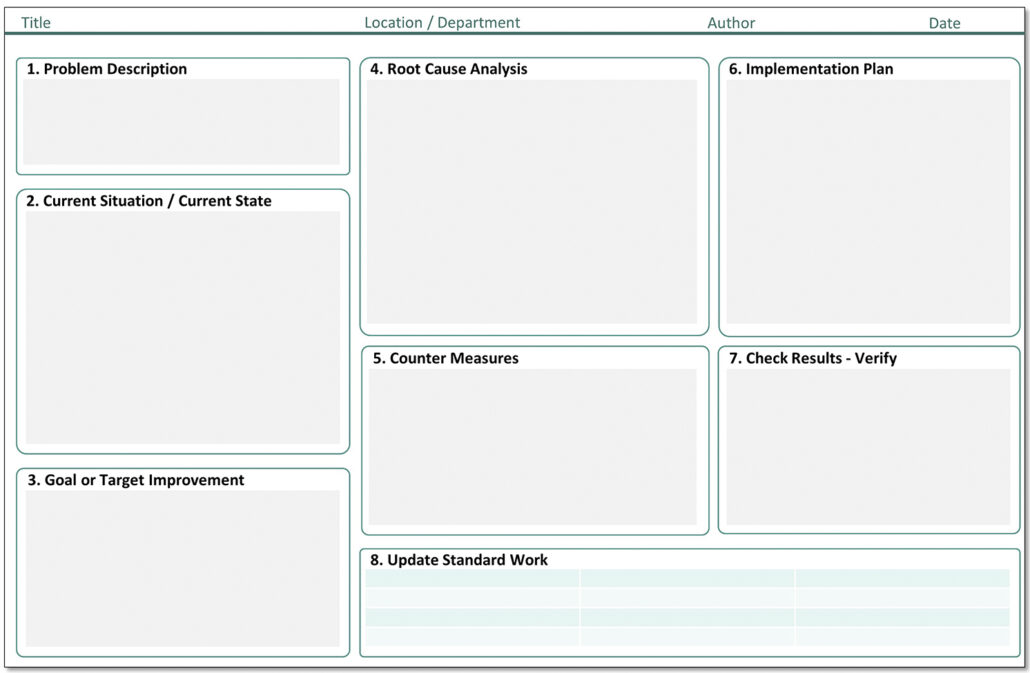

There are four primary types of A3s: Proposal, Problem Solving, Status and Information. Problem Solving is the primary document and the one that is most used in Operational Excellence. An A3 template example is shown here:

A3 Template for solving operational process problems in production, services, functions.

**If you would like PowerPoint versions of our A3 template, drop us an email at

hello <@> kaufmanglobal.com and we’ll send one to you.**

The major headings can be slightly adjusted according to the problem type and application.

Mistakes to Avoid

- Do not treat the A3 simply as a template to be filled in. It is a learning tool. Be sure to engage, communicate, discuss and brainstorm as you move through the process

- Do not be afraid to change the headings, box size and content. Anything that tells a better story is fair game

- Do not expand content beyond the A3 paper size and do not shrink font below size 11

- Recognize that this tool is the tip of the iceberg – there is a lot of work below the surface

A pre-Lean organization may have a difficult time using this technique because transparency and collaborative problem solving are often lacking.

« Back to Glossary Index